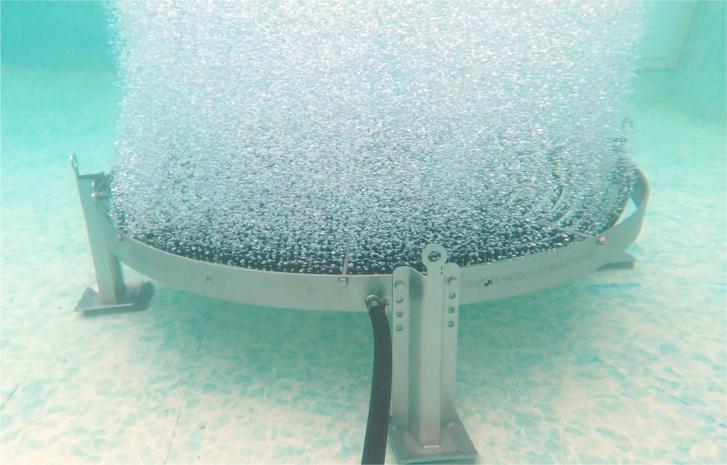

The OctoAir is a Canadian-made, industrial-grade diffuser designed for aeration, oxygenation, and de-icing. Built for industrial and municipal applications, it resists corrosion, pH variations, extreme temperatures, water salinity, and a wide range of chemicals. The Bubble Tubing® is secured in a spiral using an integrated steel support for durability and stability.

Available in two models, the OctoAir-10 and OctoAir-60, both units are highly efficient and easily maneuverable. Installation teams consistently report that the OctoAir is simple to install, easy to maintain, and thoughtfully engineered for reliable, long-term performance.

Deicing video with Octoair diffuser:

Aeration video with Octoair diffuser:

Specifications - Compare our two OctoAir models

| OCTOAIR-10 | OCTOAIR-60 | ||

|---|---|---|---|

| SPECIFICATIONS | Applications | - Aeration - Deicing - Mixing - Reduction of pathogens |

- Aeration - Deicing - Mixing - Reduction of pathogens |

| Diffuser | - Stainless steel 304 frame - 4 adjustable legs* - 100 ft (30 m) 1/2" Bubble Tubing®, non weighted - Check valve NOT INCLUDED: - Torpedo Tubing Airline Feeder Hose - Compressor |

- Stainless steel 304 frame - 4 adjustable legs* - 300 ft (90 m) 3/4" Bubble Tubing®, non weighted - Check valve NOT INCLUDED: - Torpedo Tubing Airline Feeder Hose - Compressor |

|

| Delivery | Assembled | Unassembled (assembly required) | |

| Warranty | 1 year | 1 year | |

| Options | Marker Buoy Anodes for salt and/or brackish waters |

Marker Buoy Anodes for salt and/or brackish waters |

|

| DIMENSIONS | Diameter | 48'' (122 cm) | 96'' (244 cm) |

|

Weight |

65 lb (29,4 kg)** | 315 lb (143 kg) | |

| Assembly | Legs only | Required | |

| PRESSURE | Maximum | 50 PSI (3,4 BAR) | 70 PSI (4,8 BAR) |

| Minimum | 20 PSI (1,4 BAR) | 20 PSI (1,4 BAR) |

(*) The raised adjustable legs keep the Bubble Tubing® off the basin floor. Custom-made legs available upon request.

(**) Several OctoAir-10 can be stacked one on top of the other to facilitate transportation on pallets.

(***) Unit manufactured in SS316 is also available upon request.

Tech Sheet OctoAir (PDF)

The OctoAir-60 was specifically designed for large-scale aeration and industrial de-icing projects. With an air flow rate of up to 75 CFM, its 300 feet of ¾” Bubble Tubing® integrated within the diffuser structure delivers exceptional oxygen transfer performance. The design allows air to be fed into the tubing from both ends, maximizing efficiency and flexibility.

Engineered for industrial-strength applications, the OctoAir-60 combines corrosion resistance, easy maneuverability, and high performance, making it ideal for demanding aeration and de-icing projects.

How OctoAir’s Work

Compressed air is pushed through the airline feeder hose to the OctoAir diffuser. Microbubbles are released along the entire length of the Bubble Tubing®, providing high oxygen transfer rate while creating a strong upward current that moves warmer water against the ice. By introducing air into the water, the OctoAir promotes optimal circulation and assists in ice melting.

Once installed, the OctoAir provides reliable and efficient ice prevention, even in extremely cold conditions.

Maintenance

OctoAir diffusers should be cleaned once per year (depending on water conditions) using Ecopurge. The diffuser can remain in the water during cleaning, as the solution is poured directly into the airline via the compressor, making maintenance simple and convenient.

Security

Before installing an OctoAir intended for de-icing, confirm with local authorities that de-icing is permitted in your municipality. Thin ice and open water areas should be clearly identified with warning signs. This precaution is necessary for all types of de-icing and defrosting systems. Click here to purchase a Thin Ice Warning Sign.

The purpose of a case study is to examine a specific instance or situation in its natural context, by examining real-world cases, researchers can refine or challenge established theoretical frameworks.

Case Study : Deicing in a Retention Basin to Increase Water Availability in Mining.